EXPEDIENTE INDEX

- Introduction: The Whispers of Forgotten Forges

- The Anomaly: An Ancient Lathe Factory Discovered

- Centralized Megalithic Production: A Paradigm Shift

- Spare Parts and Prototypes: Evidence of Advanced Planning

- The Testing Area Hypothesis

- Lost Machining Technology: A Reassessment

- Colossal Lathe Machines: Engineering Marvels

- Interchangeable Parts and Precision Engineering

- Investigator's Verdict: A Manufacturing Hub or a Geological Anomaly?

- The Researcher's Archive

- Research Protocol: Analyzing Megalithic Evidence

- Frequently Asked Questions

- Your Field Mission: Investigate Local Mysteries

Introduction: The Whispers of Forgotten Forges

The earth holds its secrets close, but sometimes, it yields them to persistent inquiry. We often visit ancient temples, marveling at their architectural grandeur and the sheer audacity of their construction. Yet, what if the true marvel lies not in the finished edifice, but in the hidden workshops where these colossal stones were brought to life? In Karnataka, India, a discovery is challenging our understanding of ancient capabilities: a vast site pointing not to an isolated construction effort, but to a sophisticated, centralized pillar manufacturing operation that rivals modern industrial complexes. This isn't just about pillars; it's about questioning the very nature of ancient technology.

The Anomaly: An Ancient Lathe Factory Discovered

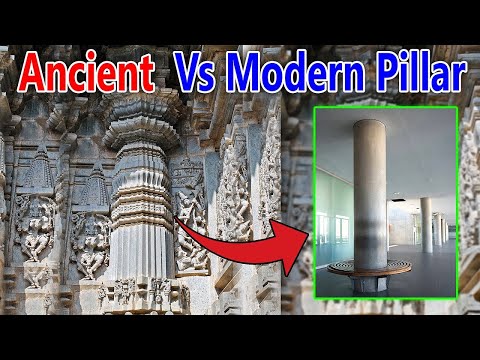

The site in Karnataka presents an unprecedented tableau: over a hundred distinct pillars, many bearing the unmistakable marks of lathe turning. This isn't a collection of naturally occurring stones or haphazardly carved blocks. The uniformity and precision in their shaping strongly suggest the application of advanced mechanical processes. Archaeologists themselves acknowledge that achieving such cylindrical perfection would necessitate a rotating mechanism, akin to a lathe. The presence of what appear to be raw materials, partially finished pieces, and completed pillars in one integrated location points towards a dedicated manufacturing hub, a concept that reshapes our narrative of ancient civilizations.

Centralized Megalithic Production: A Paradigm Shift

While it's common to assume that temple components were fabricated on-site, the evidence in Karnataka, and similar sites like the one observed in Warangal Fort, suggests otherwise. These locations appear to function as ancient megalithic factories, specializing in the mass production of temple parts. This centralized approach implies a level of organization, logistical planning, and technological know-how far exceeding conventional estimates. Pillars, once manufactured and possibly even fitted with components like male projections and female sockets for assembly, would then be transported to their final temple destinations. This division of labor and specialization is a hallmark of advanced societies, forcing us to reconsider the timeline and capabilities of our ancestors.

"The site is not merely a collection of stones; it's a tangible testament to a lost era of engineering prowess, where precision and scale were apparently mastered." Alejandro Quintero Ruiz (Investigator)

Spare Parts and Prototypes: Evidence of Advanced Planning

The sheer variety among the pillars is astounding. While they share a common theme, closer examination reveals that no two pillars are identical. This diversity, combined with the presence of what seem to be "spare parts" – unfinished pillars left unpolished, perhaps held in reserve or serving as prototypes – indicates a meticulous approach to design and production. The discovery of a pillar with a perfect square hole on top, a "female pillar" designed to interlock with a "male pillar" component, further underscores this sophisticated planning. It speaks to an understanding of modular construction and interchangeable parts, a concept we often associate with much later technological developments.

The Testing Area Hypothesis

The open spaces surrounding the main cluster of pillars, coupled with the unique shapes and formations of some stones, could suggest a designated testing or assembly area. Were these spaces used to trial different configurations, test the fit of components, or perhaps even demonstrate the assembly process before transport? The sheer scale of the site, with pillars ranging from three to seven feet in height, implies that experimentation and quality control were integral to the manufacturing process. The intricate details, like the example resembling a long-geared shaft, further fuel speculation about the specialized machinery employed.

Lost Machining Technology: A Reassessment

The pillars exhibit a level of finish and precision that modern archaeology struggles to fully explain using known ancient techniques. The lathe-turned surfaces and the complex joinery implied by the male and female pillar designs point towards a lost machining technology. Were these accomplishments achieved through brute force and simple tools, or did ancient artisans possess knowledge of complex mechanical principles and specialized equipment that has since vanished from the historical record? The evidence compels us to question our assumptions about the technological ceiling of ancient civilizations.

Colossal Lathe Machines: Engineering Marvels

To create pillars of this magnitude and precision would require machinery of considerable scale and sophistication. The concept of "giant lathe machines" is not mere speculation but a logical deduction from the physical evidence. Imagine the engineering required to rotate massive stone cylinders with a high degree of accuracy. This implies an understanding of power transmission, material science, and mechanical engineering that challenges the narrative of primitive tool use. The sheer number of finished and unfinished pillars suggests a sustained, large-scale manufacturing operation, not an isolated experimental phase.

Interchangeable Parts and Precision Engineering

The evidence of distinct male and female pillar components, designed to fit together seamlessly, is a groundbreaking revelation. This points to a sophisticated understanding of metrology and precision engineering. The ability to produce multiple components, each unique yet designed to interlock with specific counterparts, suggests advanced manufacturing protocols. It implies that ancient builders were not only capable of quarrying and shaping stone but also of producing standardized, interchangeable parts with remarkable accuracy, a feat unheard of in many historical periods.

Investigator's Verdict: A Manufacturing Hub or a Geological Anomaly?

The site in Karnataka presents a compelling case for an ancient, centralized pillar manufacturing facility. The uniformity of wear, the lathe-turned finishes, and the evidence of interlocking components strongly argue against natural geological formations. While some might propose alternative explanations, the sheer concentration and variety of shaped pillars in a single location, coupled with implied tooling marks, lean heavily towards an artificial origin. The challenge for conventional archaeology is to reconcile this evidence with existing models of ancient technology. My assessment leans towards a genuine manufacturing site, one that forces a significant re-evaluation of ancient engineering capabilities.

The Researcher's Archive

For those seeking to delve deeper into the mysteries of ancient engineering and megalithic construction, several key resources offer invaluable insights:

- "The Orion Mystery: Unlocking the Secrets of the Pyramids" by Robert Bauval and Adrian Gilbert: Explores astronomical alignments and potential advanced knowledge in ancient construction.

- "Fingerprints of the Gods" by Graham Hancock: A controversial yet thought-provoking examination of advanced ancient civilizations and their potential global reach.

- "Civilization One" by Christopher Knight and Alan Butler: Proposes theories of a sophisticated global civilization predating recorded history.

- Documentaries such as "Ancient Aliens" (History Channel) and series available on platforms like Gaia often explore fringe theories on ancient technology.

Research Protocol: Analyzing Megalithic Evidence

When encountering sites suggestive of advanced ancient construction, a systematic approach is crucial:

- Document Thoroughly: Photograph and video record all features from multiple angles, noting scale and context. Use measurements and references where possible.

- Analyze Tool Marks: Examine the surfaces for evidence of cutting, grinding, drilling, or polishing. Compare these marks to known ancient and modern tools. Look for evidence of rotary motion.

- Assess Material Properties: Understand the type of stone used and its inherent workability. Are the chosen materials consistent with the complexity of the shaping?

- Consider Logistical Challenges: Evaluate the transportation and assembly requirements for megalithic structures. Does the site provide clues about overcoming these obstacles?

- Compare with Known Sites: Cross-reference findings with established archaeological databases and research on similar structures worldwide. Look for patterns in design, technology, and location.

- Question Conventional Narratives: Be open to hypotheses that challenge established timelines or technological capabilities. The goal is to understand, not just to confirm pre-existing beliefs.

Frequently Asked Questions

Q1: Are these pillars definitively artificial, or could they be natural formations?

A1: While natural geological processes can create unusual shapes, the consistent cylindrical form, evidence of precise shaping, and the sheer number of similar pillars in one location strongly suggest artificial origin. The presence of distinct features like interlocking sockets further supports this.

Q2: What kind of technology would have been needed to create these pillars?

A2: Achieving such precision and scale would likely require advanced techniques involving rotating mechanisms (lathes), sophisticated cutting and grinding tools, and a deep understanding of material science and engineering. The exact nature of this technology remains a subject of intense speculation.

Q3: How were these massive pillars transported to ancient temples?

A3: This is one of the most significant mysteries. Theories range from the use of advanced leverage and roller systems to methods involving water transport, or even technologies yet to be understood by modern science. The existence of a centralized factory implies a robust transport infrastructure.

Your Field Mission: Investigate Local Mysteries

The world is full of enigmatic sites and unexplained phenomena. Your mission, should you choose to accept it, is to become an investigator in your own right. Identify a local legend, an unusual geological formation, or an architectural oddity in your area. Apply the principles of rigorous observation and documentation discussed above. What story does the evidence tell? Could there be a hidden history or lost technology at play in your own backyard? Share your findings and hypotheses in the comments below. Let's uncover the next great mystery together.

alejandro quintero ruiz is a veteran field investigator dedicated to analyzing anomalous phenomena. His approach combines methodological skepticism with an open mind to the inexplicable, always seeking the truth behind the veil of reality. His extensive fieldwork and rigorous analysis have positioned him as a leading voice in the exploration of the world's greatest mysteries.